In specialized industries, from medical device manufacturing to aerospace engineering, the demand for precision, efficiency, and space optimization is relentless. Standard, off-the-shelf equipment often falls short of meeting the unique and stringent requirements of these fields. This has paved the way for a new wave of compact technologies designed to deliver powerful performance in a minimal footprint. These innovations are not just smaller versions of their larger counterparts; they are highly engineered solutions that offer enhanced control, reliability, and integration capabilities. This article explores four key compact technologies that are making a significant impact on specialized industrial applications, enabling advancements that were once considered impossible.

1.Miniature Pneumatic & Hydraulic Systems

Traditional pneumatic and hydraulic systems are known for their power, but also for their bulk. For applications where space is at a premium, such as in portable medical equipment or robotics, miniature systems have become a game-changer. These compact powerhouses deliver precise force and motion control in a fraction of the size. For instance, in surgical robotics, miniature pneumatic actuators provide surgeons with haptic feedback and incredibly precise control over surgical instruments, enhancing procedural accuracy and patient safety.

The key to their effectiveness lies in advancements in material science and manufacturing. Using lightweight alloys and advanced polymers, manufacturers can create components that are both durable and light. Furthermore, micro-machining techniques allow for the production of intricate valves and cylinders with tight tolerances, ensuring leak-free and highly efficient operation. When selecting these systems, it is crucial to consider factors like pressure ratings, flow rates, and material compatibility to ensure they meet the specific demands of the application.

2.Advanced MEMS Sensors

Micro-Electro-Mechanical Systems (MEMS) have fundamentally changed how we measure the physical world. These tiny sensors, often smaller than a grain of rice, can detect changes in pressure, acceleration, temperature, and more with remarkable accuracy. In the automotive industry, MEMS accelerometers are essential for airbag deployment systems, while in aerospace, MEMS pressure sensors monitor cabin pressure and altitude. Their small size allows them to be embedded directly into critical components without adding significant weight or bulk.

A major advantage of MEMS technology is its scalability and cost-effectiveness. Fabricated using semiconductor manufacturing techniques, millions of sensors can be produced on a single silicon wafer, drastically reducing costs. This accessibility has spurred innovation across various sectors. For example, specialized industrial drones now use a suite of MEMS sensors for stable flight and precise navigation, enabling them to perform complex tasks like infrastructure inspection and agricultural monitoring with unparalleled efficiency.

3.High-Efficiency Compact Air Compressors

Compressed air is a vital utility in countless industrial processes, from powering tools to controlling automated systems. However, conventional air compressors are often large, noisy, and energy-intensive. The development of high-efficiency compact air compressors has provided a solution for applications requiring a clean, reliable air source in a constrained space. These units are designed for quiet operation and optimal energy consumption, making them ideal for laboratory environments, dental clinics, and specialized manufacturing cells.

Many of these smaller systems are engineered for specific operational demands. For example, a custom OEM compressor can be designed to meet the exact pressure, flow, and duty cycle requirements of a piece of medical diagnostic equipment, ensuring seamless integration and performance. Oil-free designs are particularly important in industries like food and beverage or electronics manufacturing, where air purity is non-negotiable to prevent product contamination. The move toward these specialized compressors not only saves physical space but also contributes to lower operational costs and a safer, cleaner working environment.

4.Miniaturized Motion Control and Robotics

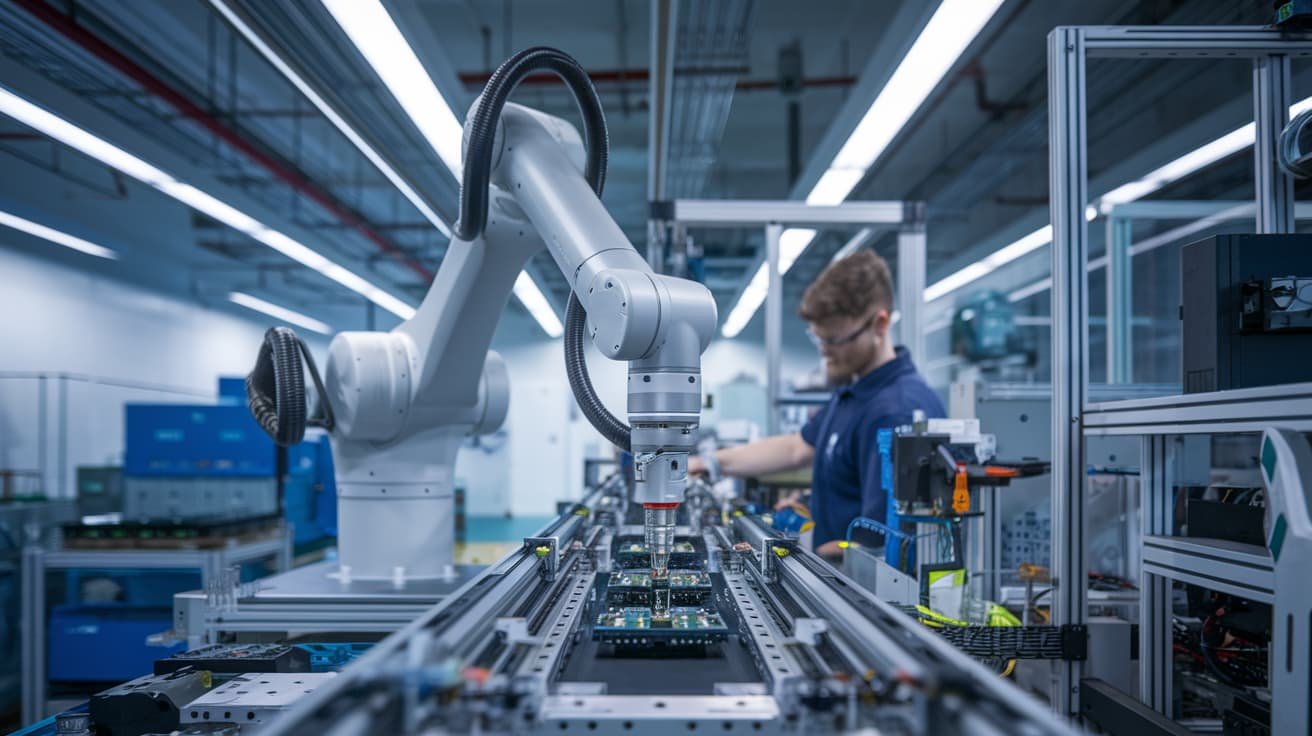

The field of robotics has seen a dramatic shift toward smaller, more agile systems capable of performing delicate and complex tasks. Miniaturized motion control components, including compact motors, drives, and controllers, are the driving force behind this trend. In electronics assembly, for instance, small-scale robotic arms equipped with high-precision servo motors can handle and place microscopic components with an accuracy that surpasses human capability. This level of precision is critical for manufacturing modern electronic devices.

These systems integrate advanced software and feedback mechanisms, allowing for real-time adjustments and collaborative operation. In pharmaceutical research, compact liquid handling robots automate the process of dispensing and mixing reagents, accelerating drug discovery and reducing the potential for human error. The ability to deploy these small robotic systems directly on a workbench or within an existing production line without major facility modifications offers a flexible and scalable approach to automation. As the technology continues to advance, these miniaturized systems will unlock even greater potential for efficiency and innovation in highly specialized fields.

Also Read–When QR Codes Meet Celebrations: Technology With a Personal Touch