Key Takeaways

- Implementing automation and AI can significantly improve feed mill efficiency.

- Adopting sustainable practices reduces environmental impact and operational costs.

- Regular equipment maintenance and staff training are crucial for optimal performance.

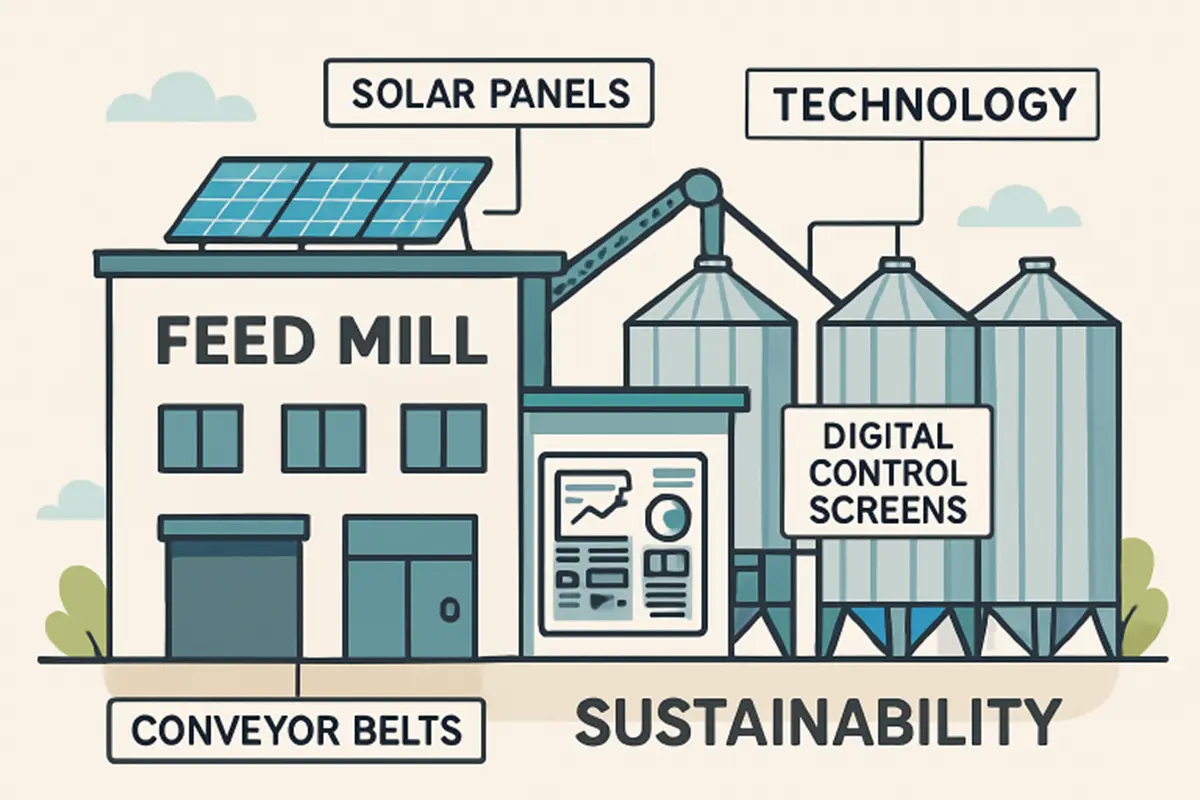

As the agricultural sector faces growing pressures to deliver more with less, feed mill operations are now at the forefront in the push for efficiency and sustainability. Improving processes in feed production is not just beneficial for business profitability, but is also crucial for meeting the evolving demands of animal nutrition, food safety, and environmental stewardship. In this context, Cruco Mill & Industrial Supply feed mill suppliers play a crucial role in connecting mills with state-of-the-art equipment and solutions, enabling them to achieve high standards in production efficiency.

Modern feed mills must adopt strategies like automation, AI, sustainable practices, and staff training to stay competitive and responsible. Optimizing production ensures a steady supply of high-quality feed, reduces waste, and lessens environmental impact, supporting industry and planetary health. As global demand for animal protein rises, those investing in efficiency and sustainability will secure a prosperous future. Using technology, data, and continuous improvement, mills can turn challenges into growth opportunities. This guide highlights effective methods for feed mill optimization, sharing real-world examples and expert insights for managers, nutritionists, and bio stakeholders to enhance resilience and efficiency.

Automation and AI Integration

Automation and AI are transforming feed mill operations by integrating controls, sensors, and analytics to monitor ingredients, predict needs, and optimize processes in real-time. These technologies reduce human error, lower labor needs, and allow dynamic formulation for different animals and growth stages. AI systems quickly analyze variables like moisture, temperature, and ingredient variability, providing precise adjustments that improve feed quality, consistency, and cost savings by reducing waste and maximizing resources.

Sustainable Practices in Feed Production

Sustainability is now essential. Feed mills are adopting new practices and technologies to cut their carbon footprint and resource use while maintaining or improving output. Using alternative proteins, such as insect meal or algae-based ingredients, significantly reduces environmental impact and provides vital nutrients essential for animal health. Energy-efficient systems, such as variable frequency drives and heat exchangers, reduce utility bills and greenhouse gas emissions. Some mills incorporate solar panels and wind turbines to offset their energy consumption. Innovations in recycling and water conservation show that sustainable feed production is practical and profitable.

Regular Maintenance and Staff Training

To optimize feed mill performance, prioritize regular maintenance and staff training. Well-maintained machinery runs efficiently, reduces breakdowns, and ensures consistent output. Scheduled preventative maintenance and predictive analytics can foresee failures, avoiding costly downtimes. Investing in employee development, including training on advanced equipment, safety, and industry innovations, enables quick troubleshooting and the adoption of best practices. This dual focus on machinery and personnel fosters accountability and long-term success.

Conclusion

Optimizing feed mill efficiency is imperative for the modern agriculture sector. By embracing automation, prioritizing sustainability, and investing in proper maintenance and people, mills can deliver high-quality feed at reduced costs, all while supporting environmental and community health. With forward-looking strategies and the right industry partners, such as specialized feed mill suppliers, the future of feed production can be both sustainable and resilient.