Key Takeaways

- Proper blast room design enhances operational efficiency and worker safety while reducing costs.

- Technological integration can achieve environmental benefits and compliance with stricter regulations.

- Customized solutions deliver higher performance by aligning with specific facility requirements.

Table of Contents

- Size and Layout

- Ventilation and Dust Collection

- Abrasive Recovery Systems

- Lighting and Visibility

- Safety Measures

- Automation and Technology Integration

- Compliance with Regulations

- Final Thoughts

Optimizing an industrial blast room is pivotal for streamlining surface preparation processes, guaranteeing operator safety, and delivering premium-quality finishes. Leveraging the solutions, expertise, and service footprint of Airblast Afc—an industry leader with decades of experience and a robust presence throughout North America and the UK—ensures that businesses design and implement blast rooms built for efficiency, compliance, and long-term success. Airblast Afc’s tailored blast room solutions address the needs of sectors such as aerospace, automotive, and heavy fabrication, underscoring their authority through advanced engineering, cutting-edge dust collection, and outstanding customer support. Investing in the right Blast Room pays dividends in workflow improvements, regulatory compliance, and energy savings.

From selecting the appropriate room dimensions to integrating the latest technologies, every design decision impacts worker productivity, maintenance costs, and the quality of finished blasted components. This comprehensive guide covers the essential considerations and proven best practices for creating an optimal blast room environment, helping maintenance managers, safety supervisors, and facility engineers make informed decisions for superior outcomes.

Size and Layout

Determining the optimal size and configuration is the backbone of blast room efficiency. The space must be large enough to comfortably handle the largest parts processed, allowing operators to move with safety and ease. Poorly planned layouts not only create chokepoints but also increase the risk of trip hazards, equipment collisions, and workflow bottlenecks. When Morton Industries brought blasting in-house with a custom-configured blast room, they cut production lead times by four weeks. They gained the flexibility to take on new projects requiring specialty surface preparation. Thoughtful design also encompasses staging and transition areas to segregate cleaned items from those yet to be processed, further refining operational throughput.

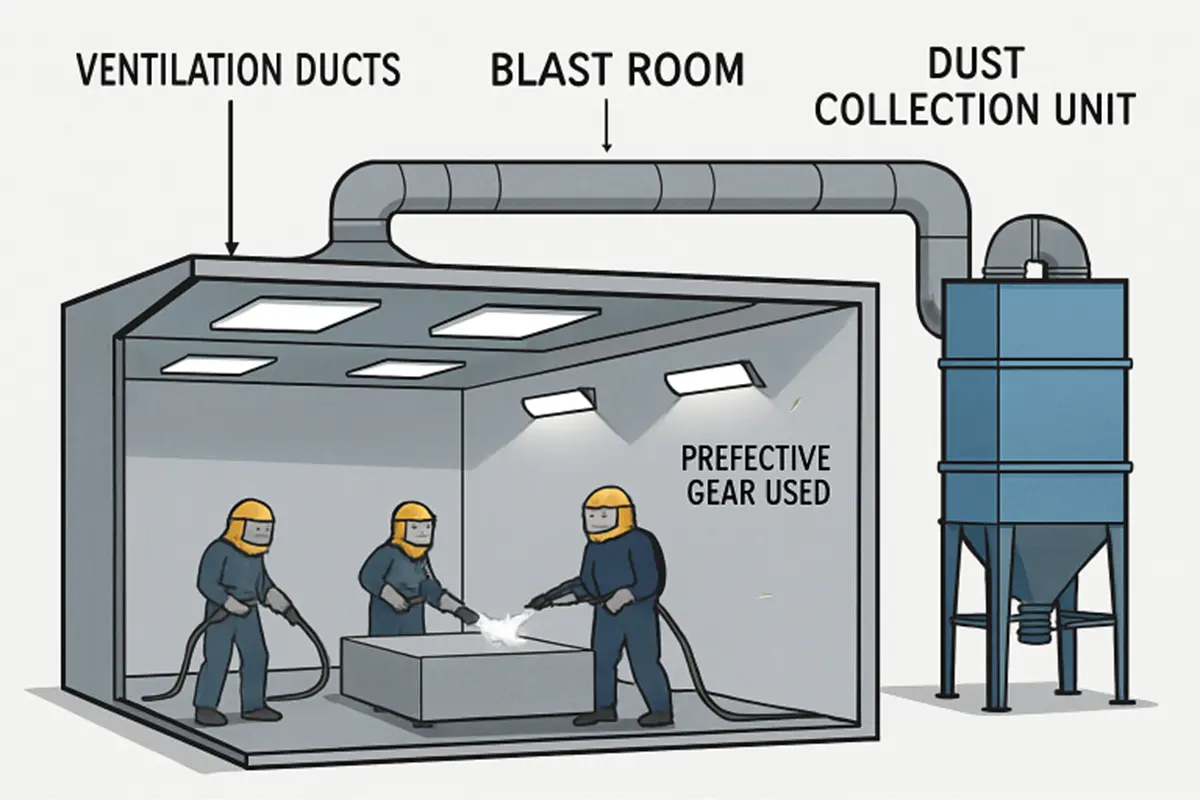

Ventilation and Dust Collection

Airflow design is critical in any industrial setting, but it is especially essential in a blast room. Advanced ventilation systems clear the air of airborne dust and spent abrasive, maintaining clean air for operators and meeting OSHA or EPA standards. Upgrades such as high-efficiency cartridges or HEPA filtration dramatically reduce respirable dust, thereby extending the lifespan of machines and improving the work environment. Facilities that choose premium filtration systems benefit from reduced filter change-outs, lower maintenance demands, and peace of mind that both workers and the local environment stay protected.

According to industry leaders, optimizing dust collection not only safeguards worker health but also decreases environmental impact and helps businesses remain competitive by demonstrating adherence to strict regulatory requirements. These efficiencies enable teams to focus on productivity rather than time-consuming clean-ups.

Abrasive Recovery Systems

Modern abrasive recycling is one of the most effective strategies for driving down operating costs while maintaining consistent results. Automated reclamation equipment—such as magnetic separators and air-wash classifiers—continuously filter out debris, separating reusable media from dust and spent particles in real time. This leads to substantial material savings of up to 30–40% annually and preserves the quality of blast media for uniform surface results on every project.

Efficient abrasive recovery isn’t just about economics. Improved systems reduce the frequency and difficulty of manual media handling, minimizing the potential for accidents and ergonomic injuries while supporting higher productivity. Investing in a robust recycling system is essential for large industrial facilities processing high-throughput volumes, but even smaller operations see clear benefits in sustainability and safety metrics.

Lighting and Visibility

In high-intensity industrial environments, excellent lighting is indispensable. Insufficient or poorly distributed lighting increases the odds of operator error and fatigue, jeopardizing both product quality and worker welfare. Incorporating energy-efficient LED fixtures assures not only superior illumination but also reduced energy expenditure and downtime due to fewer lamp replacements. Operators can more easily detect flaws, guaranteeing blast profiles meet the rigorous standards required in fields such as aerospace or infrastructure restoration. Proper lamp placement and shielded fixtures minimize shadows, allowing every detail to be clearly judged as the blasting cycle progresses.

Safety Measures

Safety is at the core of all efficient blast room designs. Smart safety features may include non-slip flooring, temperature-controlled helmets to prevent heat stress, and interlocked doors that automatically halt operation if opened, preventing inadvertent exposure to hazardous environments. Regular inspections and preventive maintenance further reduce the chance of breakdowns or injuries. Facilities that perform routine equipment checks and provide operator safety training foster a culture of preparedness and compliance, thereby avoiding costly work disruptions and claims.

Automation and Technology Integration

The industrial sector is seeing significant returns from integrating automated blasting solutions, notably robotic arms and digital process controls. Automated blast room systems produce a uniform finish, eliminate inconsistencies, and enable remote monitoring of critical parameters, including pressure, airflow, and abrasive flow rates. Robotics also drastically improves workplace safety by reducing direct operator exposure, making these advancements appealing for high-volume operations and industries with stringent finish requirements. The future of industrial surface preparation will continue gravitating toward intelligent, data-driven systems that save time and resources while improving precision.

Compliance with Regulations

Ongoing regulatory changes push operators to take a proactive approach to blast room design. Facilities must ensure their systems support local, state, and federal air quality and worker safety standards—which calls for up-to-date engineering controls, documented maintenance, and robust safety training. Achieving regulatory compliance not only reduces risk and liability but also builds trust with clients and demonstrates commitment to responsible operations. Keeping abreast of evolving requirements ensures that investment in a new or upgraded blast room pays ongoing dividends and avoids future costly retrofits.

Final Thoughts

Successful industrial blast room design results from a meticulous approach to space planning, safe ventilation, advanced abrasive handling, high-grade lighting, and careful integration of the latest technologies. Focusing on best practices and partnering with recognized authorities, such as Airblast Afc, ensures that organizations unlock lasting gains in efficiency, quality, and safety. An investment in the right blast room solution means a safer, cleaner, and ultimately more productive workplace for the years to come.

Also Read-How Holiday Gifting Boosts Employee Appreciation and Engagement