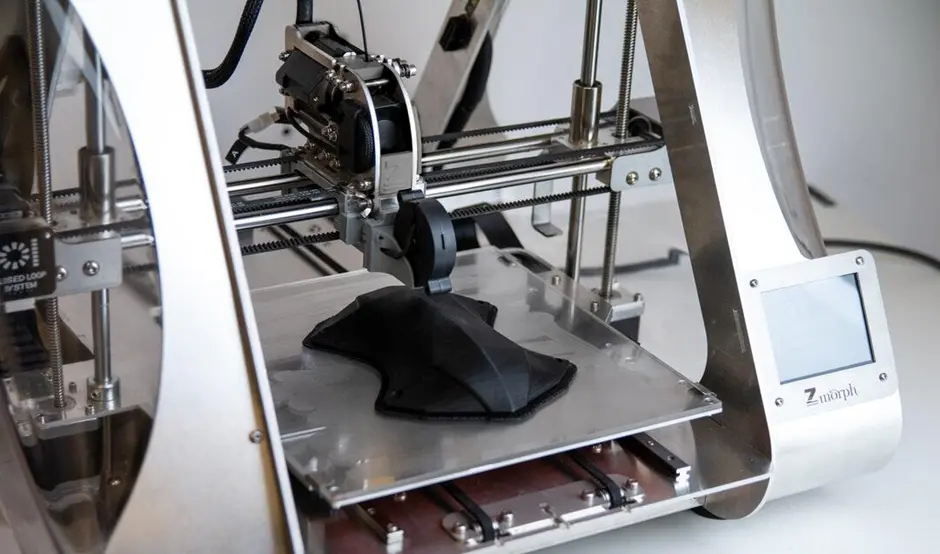

3D printing, also called additive manufacturing, is changing how products are made. What started as a way to create simple prototypes has now become a powerful tool for full-scale production. Today’s 3D printing solutions are faster, smarter, and more flexible than ever before.

They are helping businesses across many industries-like aerospace, healthcare, and manufacturing-work more efficiently and cost-effectively. Read on.

Faster Printing with New Technology

One of the biggest improvements in 3D printing is speed. In the past, printing even small parts could take hours. Now, thanks to new methods like CLIP (Continuous Liquid Interface Production), Multi Jet Fusion (MJF), and volumetric printing, production is much faster.

For example, CLIP uses light and oxygen to harden liquid resin quickly, building objects up to 100 times faster than older 3D printing methods. MJF can also produce strong, complex parts quickly, making it a great option for finished products-not just samples.

Smarter Printing with AI and IoT

Modern 3D printers are also getting smarter. Many are now powered by Artificial Intelligence (AI) and connected to the Internet of Things (IoT). AI helps improve the printing process by adjusting settings in real-time, checking quality, and reducing waste. It can also help design better parts that are easier and cheaper to print.

With IoT, printers can connect to other machines and software systems. This allows for better tracking, faster problem-solving, and less downtime. Smart systems can even alert users when maintenance is needed or when supplies are low.

New Materials for Better Products

3D printing is no longer limited to plastic. Today, printers can use many types of materials, including metal, ceramic, carbon fiber, and even materials safe for the human body.

This opens up exciting opportunities. In aerospace, lightweight metal parts are key to fuel efficiency. In healthcare, doctors can now create custom implants and prosthetics that fit each patient perfectly. New materials mean more strength, flexibility, and durability-no matter the industry.

Customization at Scale

One of the most powerful features of 3D printing is the ability to create customized items without slowing down production. Unlike traditional manufacturing, which often requires expensive molds or tools for every new design, 3D printing can adjust to new designs instantly.

This is especially useful in industries like healthcare, where every patient is different. Custom dental aligners, hearing aids, and prosthetics can be made quickly and accurately.

In consumer goods, brands can offer personalized products without raising costs. Mass customization is no longer a dream-it’s a reality with 3D printing. Make sure to consult an expert, especially on 3D printing for rapid prototyping.

Making Products On-Demand

Another major benefit of 3D printing is the ability to create parts when and where they’re needed. This is called on-demand or decentralized manufacturing.

Instead of relying on global shipping and large warehouses, companies can store digital design files and print items locally. This saves time, cuts shipping costs, and reduces waste. During the COVID-19 pandemic, this kind of flexibility helped many businesses stay afloat when supply chains broke down.

Start Using 3D Printing Today

3D printing is quickly becoming a core part of modern manufacturing. Thanks to faster printing, smarter systems, new materials, mass customization, and flexible production methods, it offers a better way to make products. Businesses that adopt these innovative 3D printing solutions can work faster, waste less, and stay ahead in a changing world.

If you want to read more articles, visit our blog.

Also Read-